Here at Ledge, we are proud of the companies who achieved business growth through innovation by partnering with us. We like to share their stories to show how they overcame obstacles through sound business strategy.

Our clients at Rhino Buckets & Attachments are renowned for their locally manufactured products, friendly team and 50+ years of experience, but are you aware of their revolutionary Viking Bucket Technology?

Revolutionary Innovation and Design

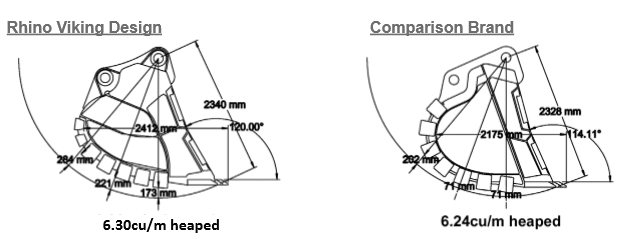

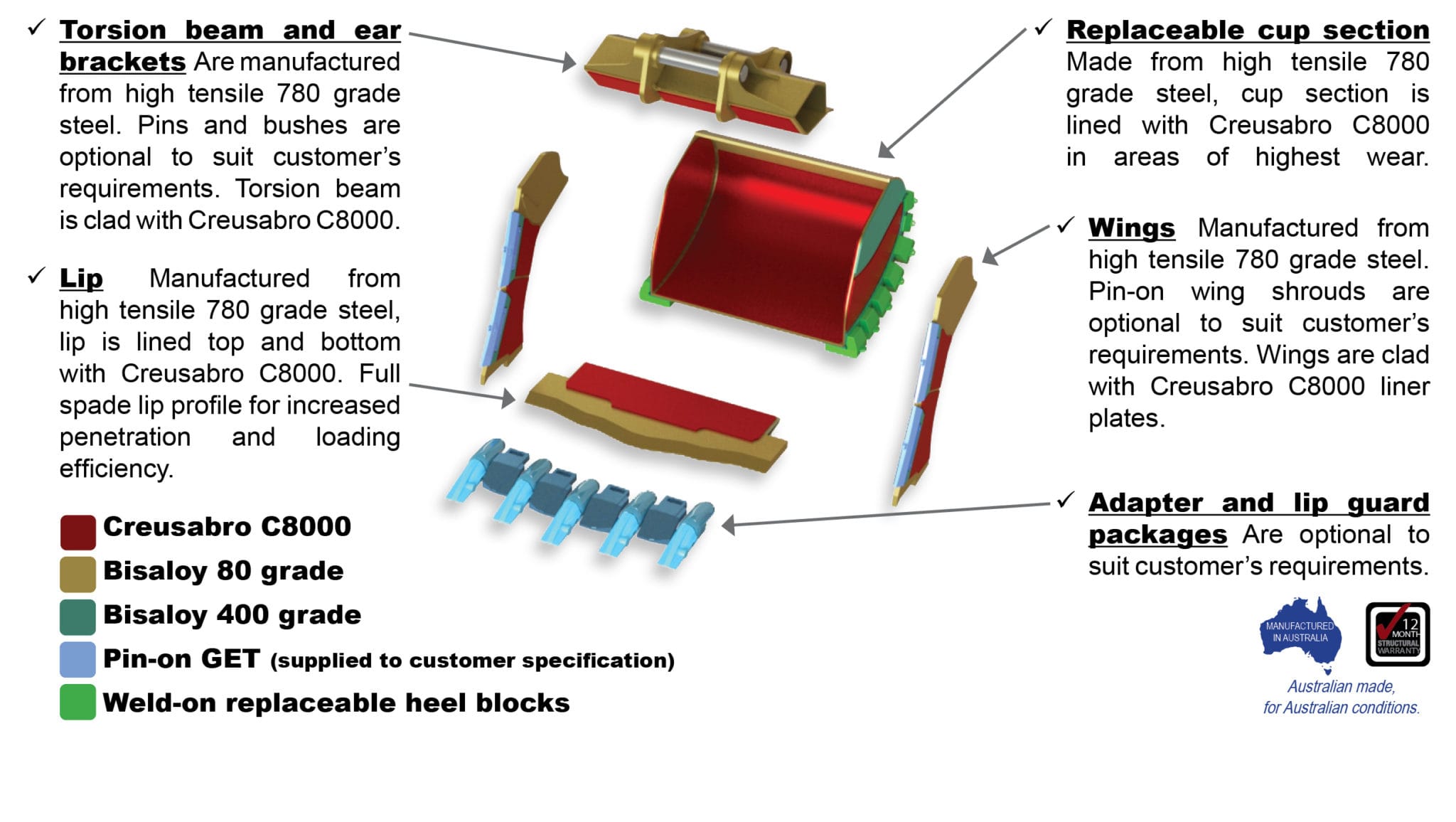

The innovation of the Viking Bucket allows you to load more material, for longer, at a lower cost than anything else available on the market. This is done through transforming the shape and geometry of the standard bucket design. The benefits of the Viking design include expanding the interior as well as reinforcing and removing the traditional wear hot-spots of excavator buckets.

Through this design, the Viking Bucket experiences reduced wear and tear, which results in reduced maintenance requirements and an extended life for the bucket. The design also boasts a perfectly balanced wear pattern, meaning that all areas of the bucket will be due for refurbishment at the same time, rather than section by section. This maximizes productivity by minimizing your buckets downtime for maintenance and refurbishment.

Rhino’s refurbishment program can even transform your regular excavator bucket into a Rhino Viking Bucket through altering its shape and correcting the inherent wear hot-spots, allowing your bucket to dig faster for less with less frequent maintenance. Transforming your current bucket into a Rhino Viking bucket can be done promptly by Rhino’s expert team, so don’t hesitate to ask.

To read more about their revolutionary Rhino Viking Bucket technology visit www.rhinobuckets.com.au.

To learn more about what Ledge can do for you, contact us today.